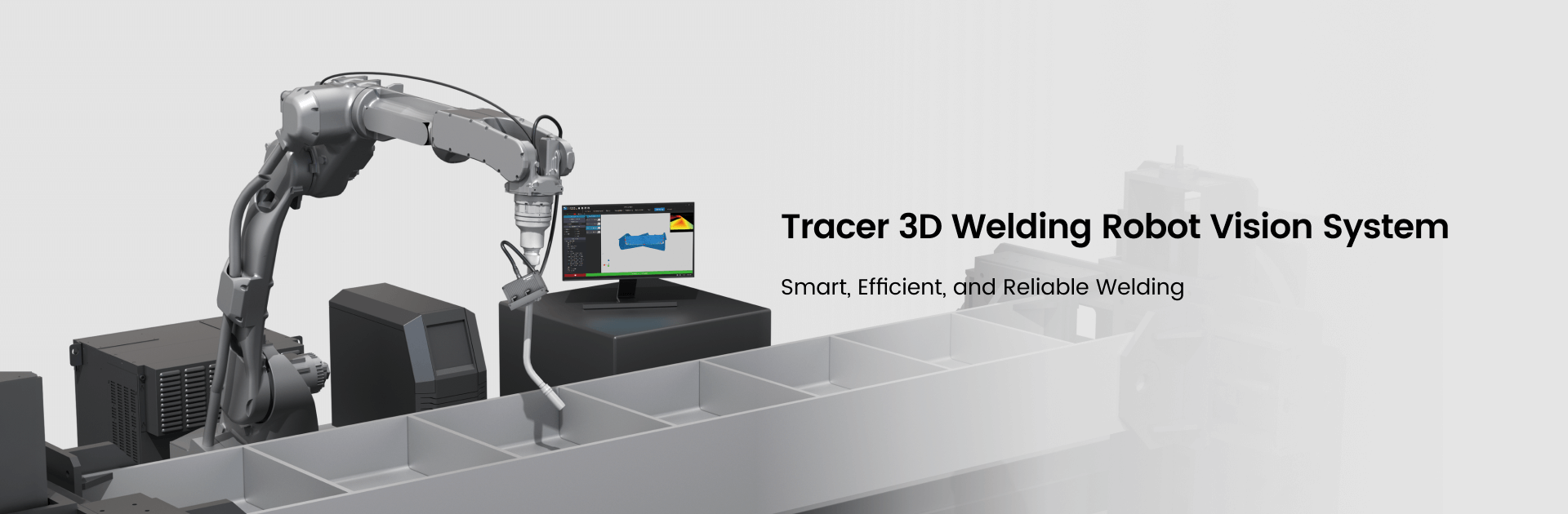

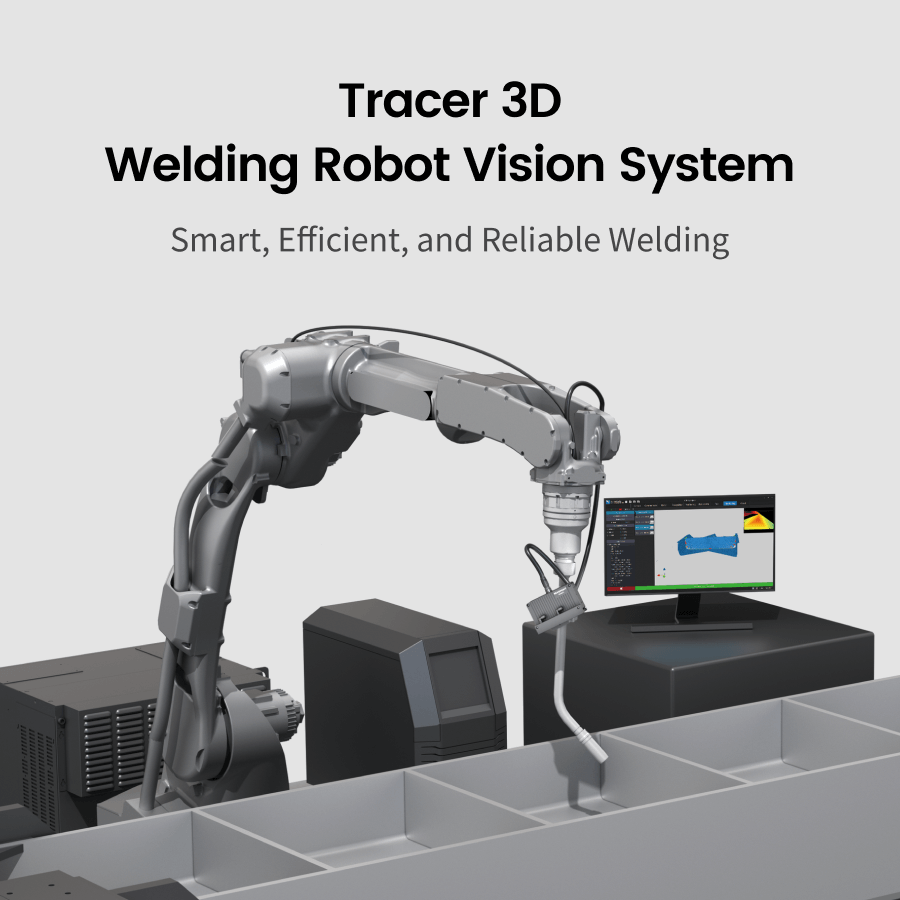

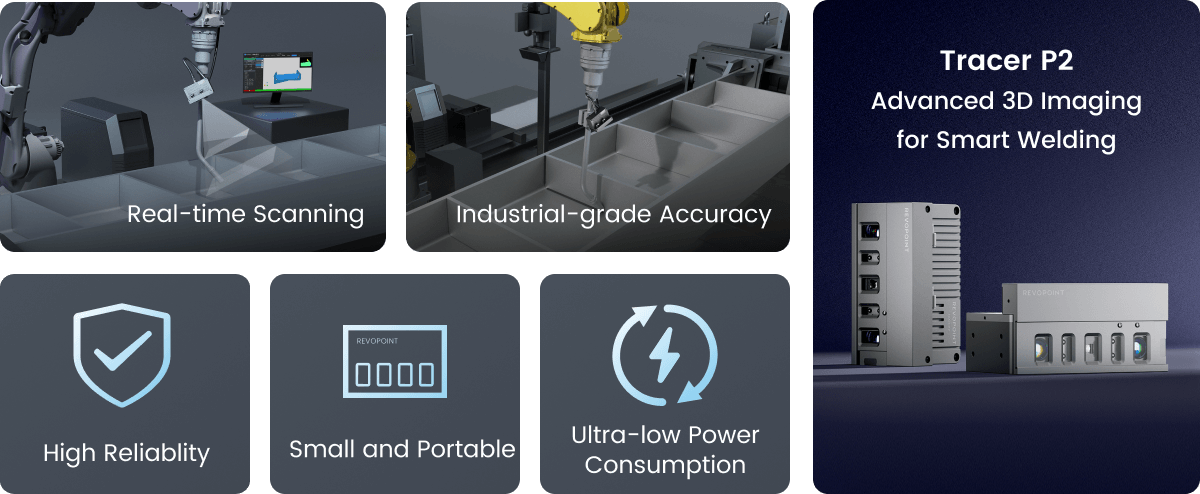

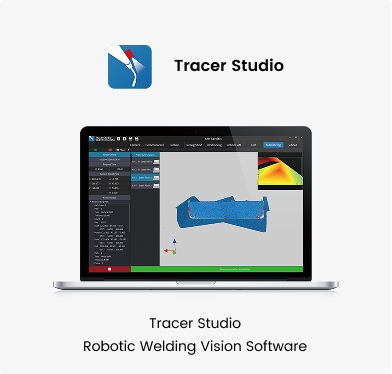

Tracer 3D Welding Robot Vision System

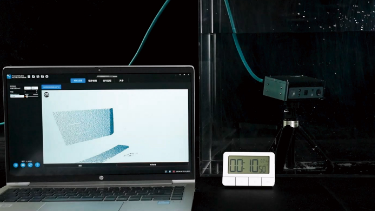

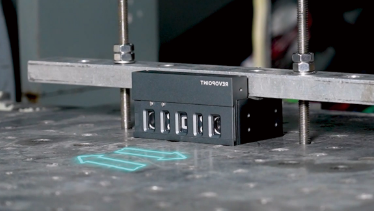

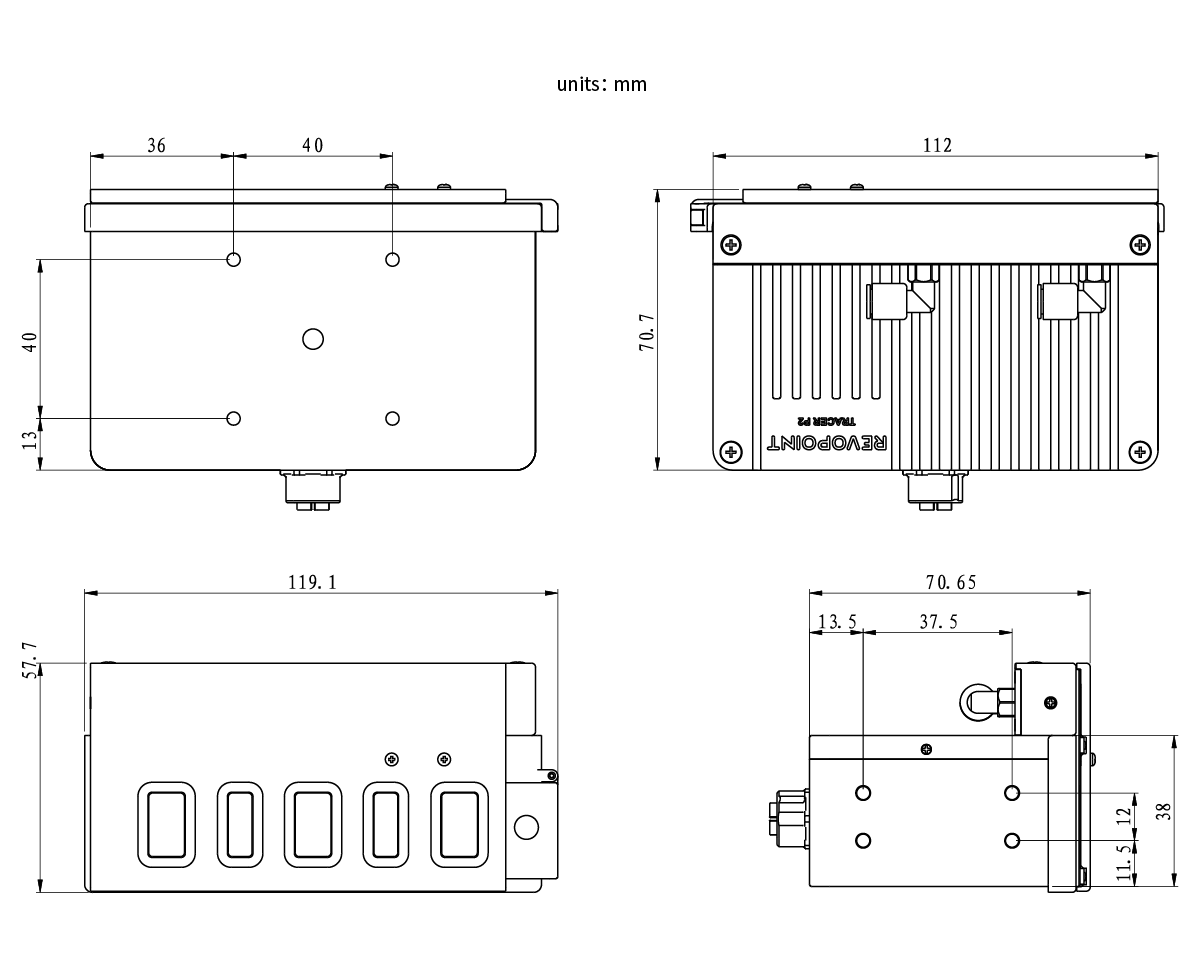

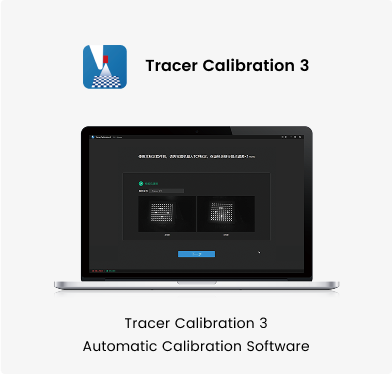

The Tracer system integrates the P Series 3D Camera, Tracer Studio software, and Tracer Studio Plus robotic vision simulation tools to deliver intelligent weld scanning and path planning for robotic welding. Compatible with most welding robots, it leverages real-time 3D data and advanced algorithms for complex weld recognition, precise path planning, and digital twin simulation. Designed for high-variation assemblies, such as steel structures, vehicle panels, and rebar, Tracer enables automated welding, boosts efficiency, and lowers labor costs.

Supported Applications

Integrates Easily With Major Robot Brands