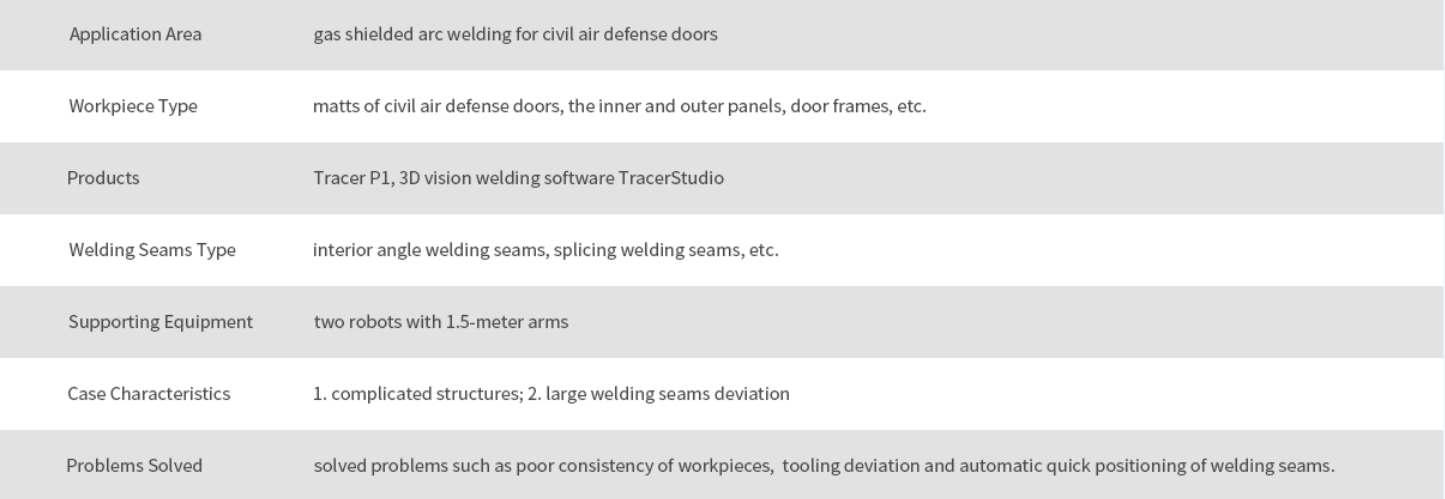

Challenges and Difficulties

At present, most civil air defense doors are welded with steel structures. The main process is to assemble the skeleton, then weld it with the inner and outer plates. Traditionally, civil air defense doors need workers to weld manually as it is easier to find unqualified welding such as misplacement or welding-missing joint. However, manual welding is low efficient and gases produced during welding are harmful to the human body, undesirable welding results such as large welding seams, uneven welding joint, slow welding, false welding or welding missing will arise as well. On the other hand, manual welding will produce inconsistent parts caused by materials, coupling and assembling errors. Meanwhile, the traditional high voltage welding wire and laser welding seams tracking methods are complicated in programming, spending much time in tracking welding seams and having high demands for positioning of welding parts. Even finishing welding, 25% of welding is unqualified, it needs workers to repair manually. Not to mention that traditional methods are not applicable for special-shaped parts like triangle iron, which has a great impact on the production efficiency of civil air defense doors.

Specific Solutions

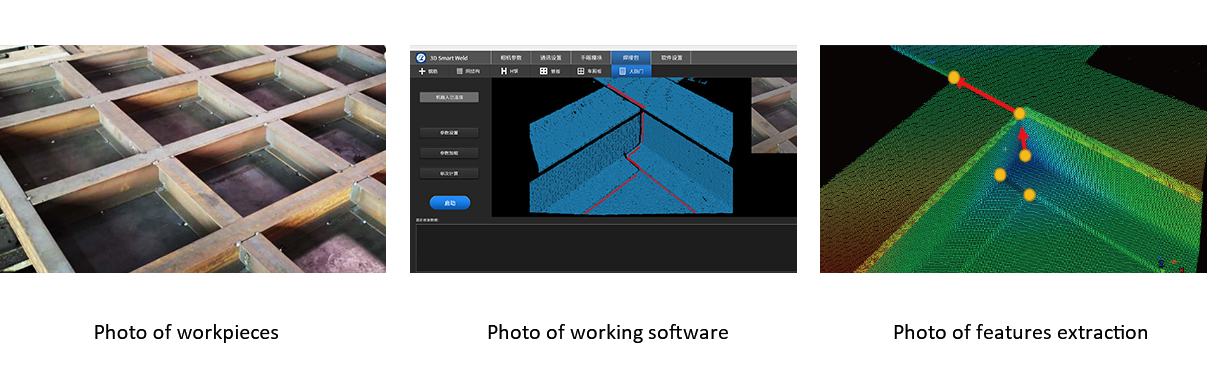

To address the above difficulties, Revopoint 3D has launched a 3D vision automatic welding solution for civil air defense doors. Tracer P1 3D camera developed based on binocular structured light technology is used to take highly accurate photos of the welding position for 3D point cloud data acquisition, then TracerStudio software platform analyzes the 3D cloud data for features of welding seams and output welding path and other parameters to robots, letting robots finish the welding. It’s noticeable that photo shooting only takes one second. Therefore, working efficiency can be greatly improved since the 8-hour working period will be replaced by automatic welding workstations, which can be working 24 hours a day and helps to reduce labor costs. Moreover, thanks to the precise positioning and refined welding operation function of the automatic welding technology of civil air defense doors, the quality and consistency of welding have also been greatly improved as the welding parameters of each welding seam are constant when the robot is welding, the requirements on the operation technology of the workers are reduced, and the welding quality is more stable and reliable. Automatic welding technology keeps workers away from the severe environment of welding arc light, smoke and splashes, etc. In the meantime, the production rhythm of robots is relatively fixed, it is helpful for enterprises to make clearer production plans and better control the production cycle and output.

Recommended Products and Service

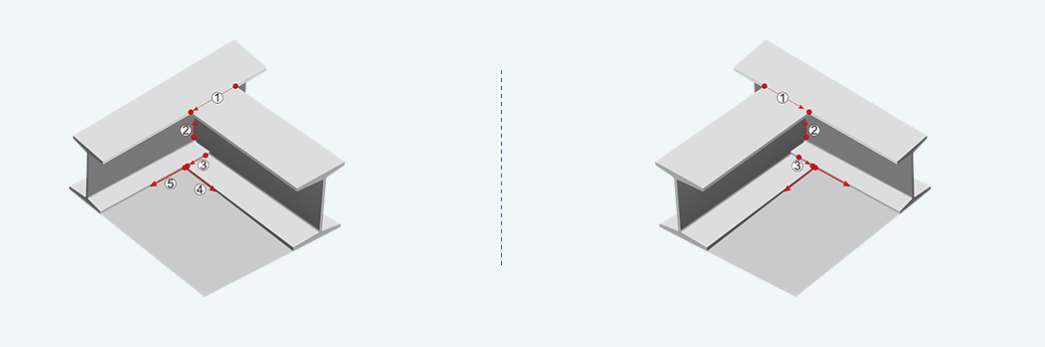

Solution Specifications

Application Cases

Guangdong Jingtai Civil Air Defense Co., Ltd has undertaken a number of civil and subway civil air defense doors projects in cities such as Guangzhou, Foshan, Zhaoqing, Dongguan, Shanwei, Meizhou, Huizhou, Maoming, etc. and has been under a big pressure of production. Previously, the company depends on manual welding to produce civil defense doors, which is low efficient and gases produced during welding are harmful to the human body , and the production environment is bad and it is lack of welders, on the other hand , undesirable welding results such as false welding or welding missing will arise as well. Then, it turned to high-voltage welding wire and laser seams tracking methods,which helps identify welds for automated welding. However, these two methods take a long time in programming and have a low success rate ,which cannot solve problems either. However, after adopting the automatic welding technology for civil air defense doors from Revopoint 3D, the company reduced the number of welding workers by 60%,and increased the production efficiency by two times and greatly reduced labor costs.

CHINA OFFICE

Office 902, 9/F, Tinno Building, Tongfa South Rd, Xili Street, Nanshan District, Shenzhen, 518000, P.R.China.

E-mail: cam.sales@revopoint3d.com

Skype: +86 18192151337

USA OFFICE

333 South Grand Avenue, Suite 403, Los Angeles, CA 90071