Challenges and Difficulties

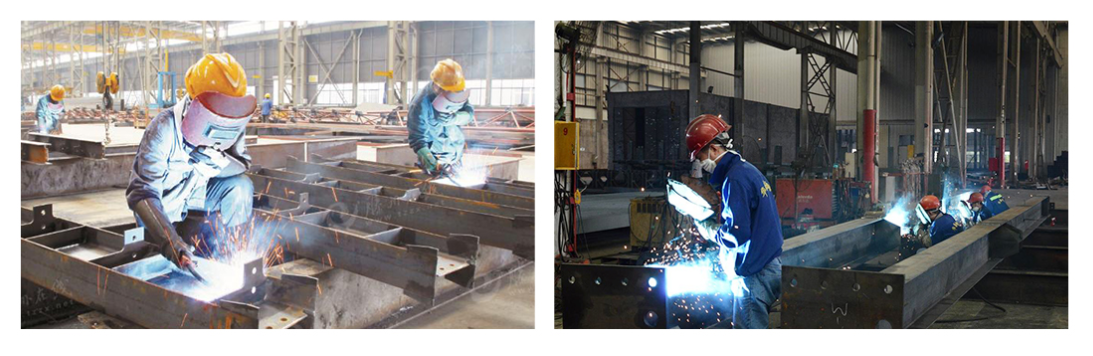

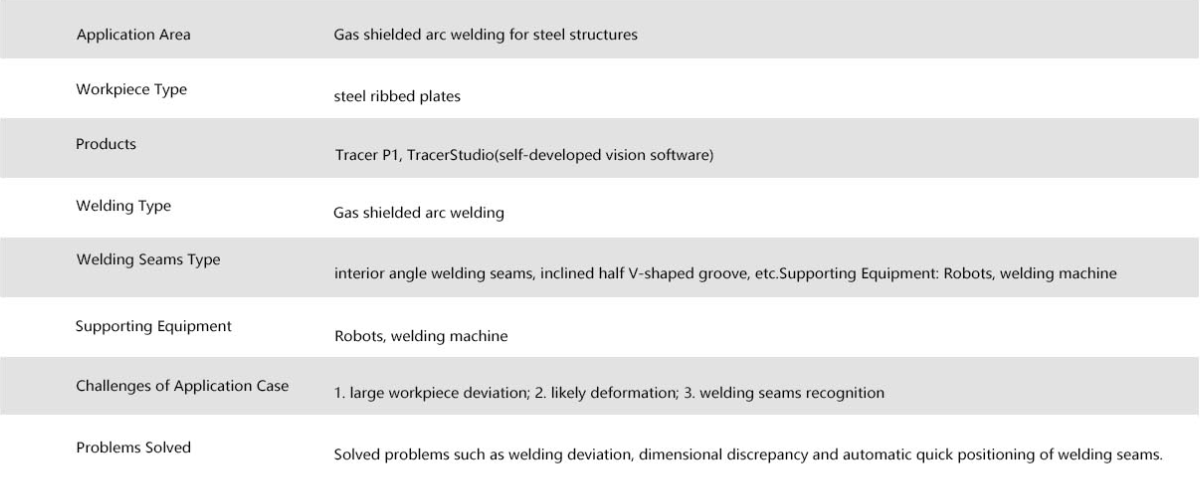

With the development of the steel structure industry, type “H” steel structures are widely used in factories, airports, high-rise buildings and bridges. Type “H”steel is a common material for steel-structured products and its needs have been rising heavily. However, when placing the workpiece, it is difficult to guarantee the accuracy, the flame or plasma cutting method also results in an accuracy error of more than ±3mm, which in return impacts the automatic welding equipment to find the exact welding position and the contact welding position tracking method is low efficient. At the same time, the production of the industry is often in a small batch, which means the prepared welding program cannot be used in mass production and it needs to program again if the factory changes parts. Moreover, many clients require customized parts and new production plans so that the adaptability of automatic welding is further reduced.

Specific Solutions

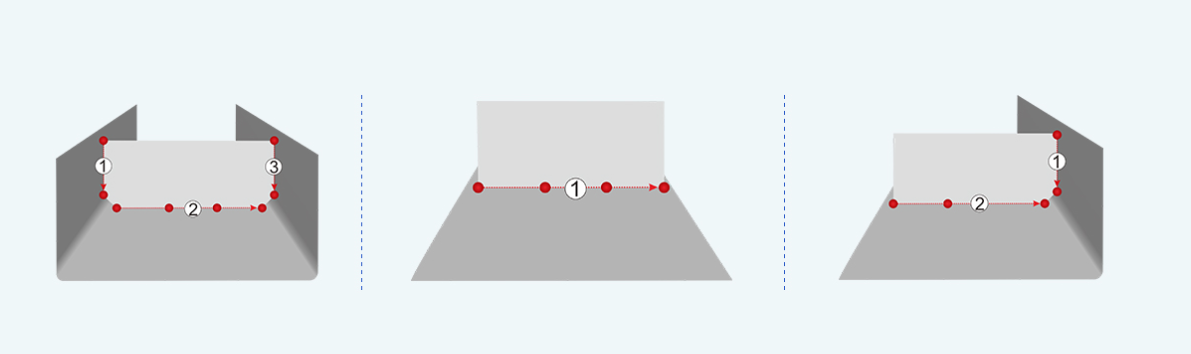

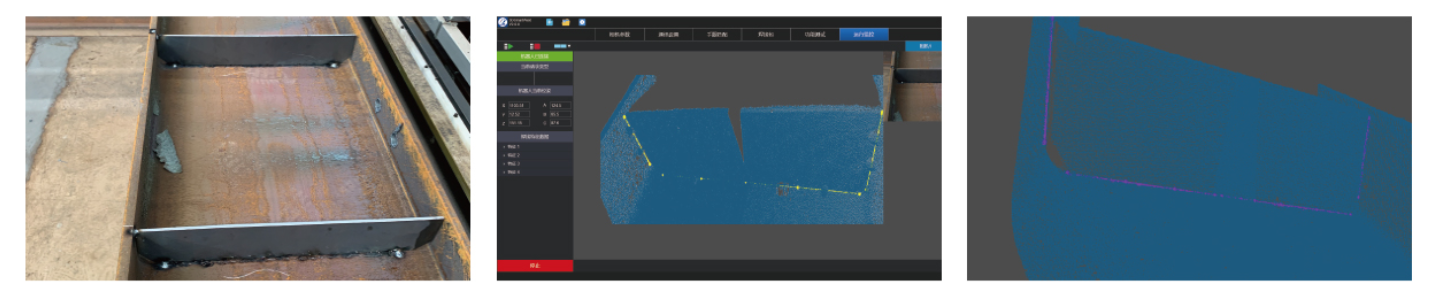

To improve the production efficiency of “H” steel structures, automatic welding is necessary way. Therefore, Revopoint 3D has launched the automatic welding technology for steel structures. The technology adopts the 3D camera Tracer P1 to take high-accuracy 3D pictures of welding seams and obtain the 3D point cloud image. The 3D vision welding software TracerStudio can get information of the seam position and types for welding robots , guiding robots to complete welding, which reduces the workload of robot teaching programming and can be used for different kinds of parts in mass production. Moreover, it only takes about 0.5 seconds to take photos and automatic welding equipment can work without interruptions all day. And the working distance of Tracer P1 ranges from 250mm to 500mm with a repetition accuracy of±1mm, which is compatible with±15mm welding seams errors, thus the requirements of previous processes also get lowered and clients could have better control of production costs. And the precise positioning and fine welding operation functions of the automatic welding technology also improve the welding quality and consistency.

Recommended Products and Services

Solution Specifications

Applications

Shijiazhuang High-strength Color Steel factory offers lightweight steel structures for factories, due to the increasing needs of production, manual labor cannot meet requirements anymore, the company seeks to replace workers with automatic welding technology. While the automatic welding technology for steel structures from Revopoint 3D has won the company’s high praise since it is equipped with the 3D camera Tracer P1 to take high-accuracy 3D photos of steel structures. With the aid of the 3D vision welding software TracerStudio, robots can obtain information of all welding seams of the part, then it can weld the part automatically and adjust the arc size accordingly. Compared with the traditional high-voltage welding wire and line laser welding location tracking, the time spent on finding the starting and endpoint of the arc is shortened by 90% with the welding success rate also increasing from 75% to 95%, which improves the operation, delivery, work pace and maintenance and other processes.

CHINA OFFICE

Office 902, 9/F, Tinno Building, Tongfa South Rd, Xili Street, Nanshan District, Shenzhen, 518000, P.R.China.

E-mail: cam.sales@revopoint3d.com

Skype: +86 18192151337

USA OFFICE

333 South Grand Avenue, Suite 403, Los Angeles, CA 90071