Challenges and Difficulties

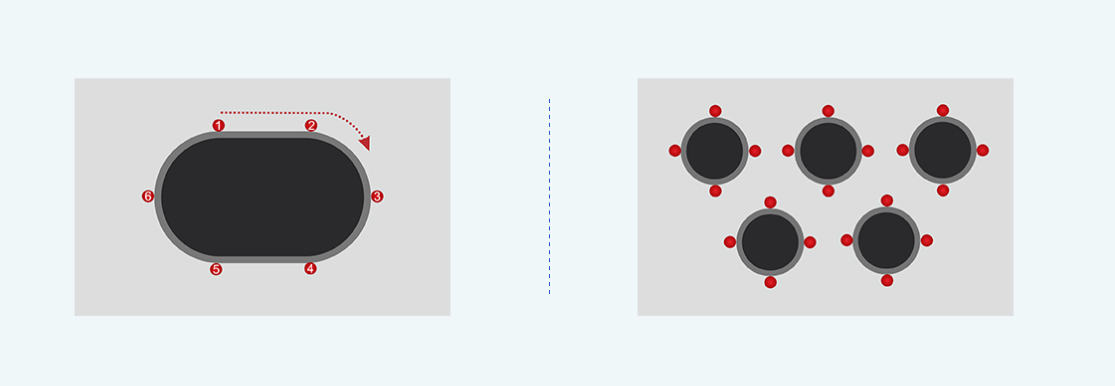

ube plate is a round steel tube as a fixation and sealing medium in heat exchangers, and it is widely used in the field of tube-type heat exchangers, boilers, pressure vessels, steam turbines and large central air conditioners, etc. It mainly used in chemical containers, such as tubular heat exchangers, pressure vessels, boilers, condensers, central air conditioners, evaporators, seawater desalination , playing the role of supporting the fixed tube. However, the accuracy during the tube plate processing, especially the distance between holes and diameter tolerance, verticality and finish greatly affects the assembly and functional performance of various equipment. Traditionally, because tube plates have poor flexibility and can not be compatible with different types of workpieces, it usually needs specific welding machine or manual work for welding. Although engineers have adopted the line laser welding location tracking method, the following challenges remain, 1. low-efficient scanning, it can not be used in dense tube plates; 2. it depends on a small number of data points to sample and fit, resulting in low accuracy; 3. it cannot handle irregular shaped tube plate structures; 4. limited tolerance for rough location.

Specific Solutions

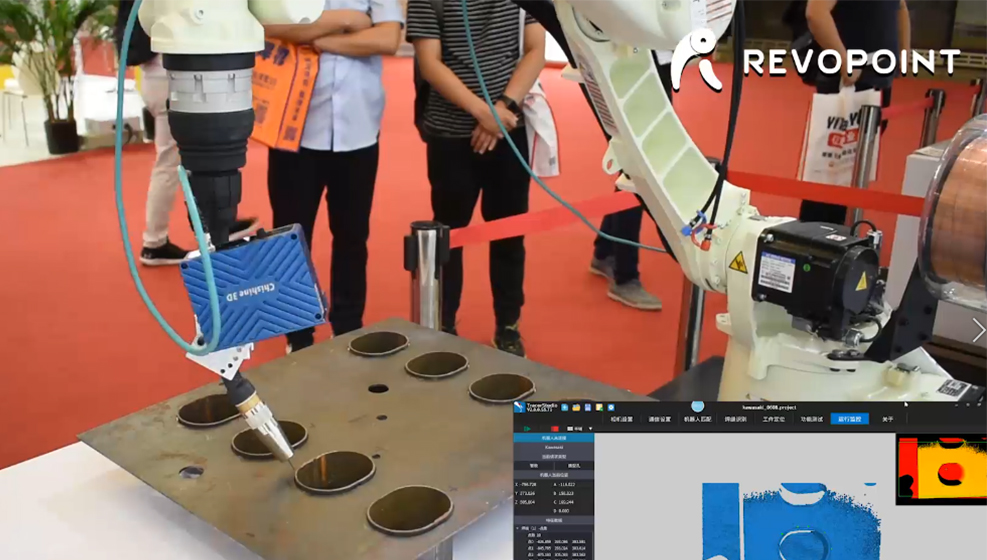

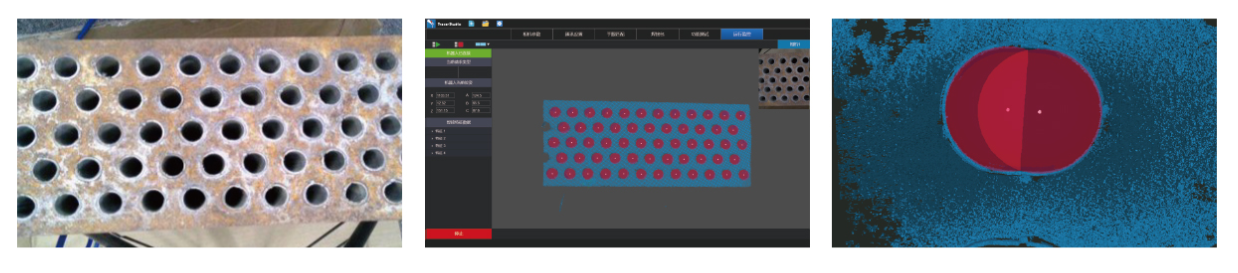

To address the growing demand for highly accurate, large-sized and thick tube plates, Revopoint 3D has launched a special 3D vision automatic welding solution, in which the Tracer P1 camera is installed on the top of the robot’s welding gun, then it can take highly accurate 3D photos of welding seams and alignment for reverse modeling, which will be used to compare with the standard parameters. If the welding process cannot be met, an alarm will send out or the process will be skipped, and manual intervention will be performed. After that, the TracerStudio software platform can analyze the 3D point cloud data and identify the welding type, then features and location data of welding seams will be sent to the robot for automatic welding.

Recommended Products and Services

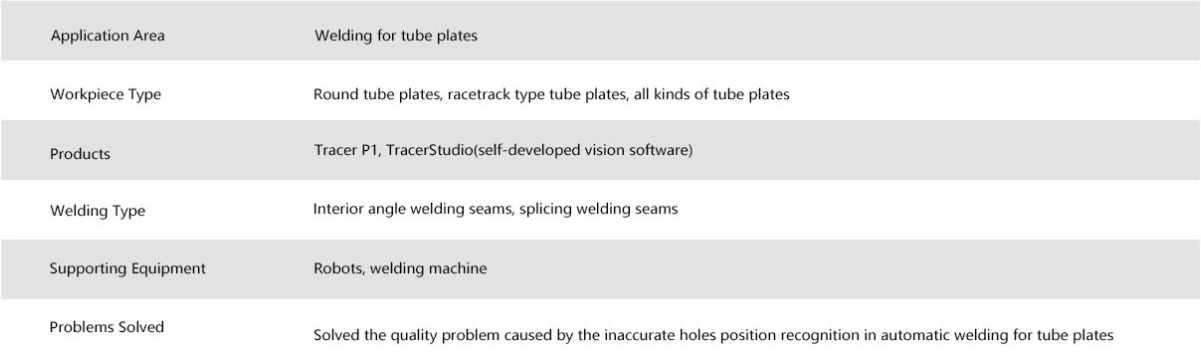

Solution Specifications

Applications

In a large thermal power plant, there are a lot of heat exchange equipment, which is made of a large number of tube plates. However, since the section of tube plates is always the waist-type holes, the traditional welding machines and laser welding location tracking method cannot produce tube plates, and they can only be produced by hands with low efficiency. After introducing 3D vision automatic welding solution for tube plates from Revopoint 3D, the company successfully performed the automatic welding and 90% of welding scenarios are automatic without humans. Because the non-stop welding robots can work 24 hours a day, human efficiency can also be increased by 300%. In the new era of manufacturing, the 3D vision automatic welding solution for tube plates from Revopoint 3D become a key for enterprises to realize automatic production.

CHINA OFFICE

Office 902, 9/F, Tinno Building, Tongfa South Rd, Xili Street, Nanshan District, Shenzhen, 518000, P.R.China.

E-mail: cam.sales@revopoint3d.com

Skype: +86 18192151337

USA OFFICE

333 South Grand Avenue, Suite 403, Los Angeles, CA 90071