Challenges and Difficulties

Steel bars are widely used in various building structures, especially in large, heavy, thin-walled high-rise building structures for reinforcement. It’s necessary to guarantee the consistency of reinforcing steel when producing, some processes can not be done by hands. For instance, the diameter of the main reinforcement used is getting larger with maximum diameter up to 50mm, The stirrups are made of cold-drawn ribbed high-strength rebar with maximum diameter up to16mm. According to load requirements, using main ribs of different diameters on the same circumference can save material . However, such requirements also put forward new requirements for steel welding , and new solutions need to solve problems such as bad-quality welded reinforcing steels or low welding efficiency caused by reinforcing steels diameter differences, welding points scattering and out of order, etc.

Specific Solutions

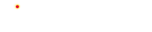

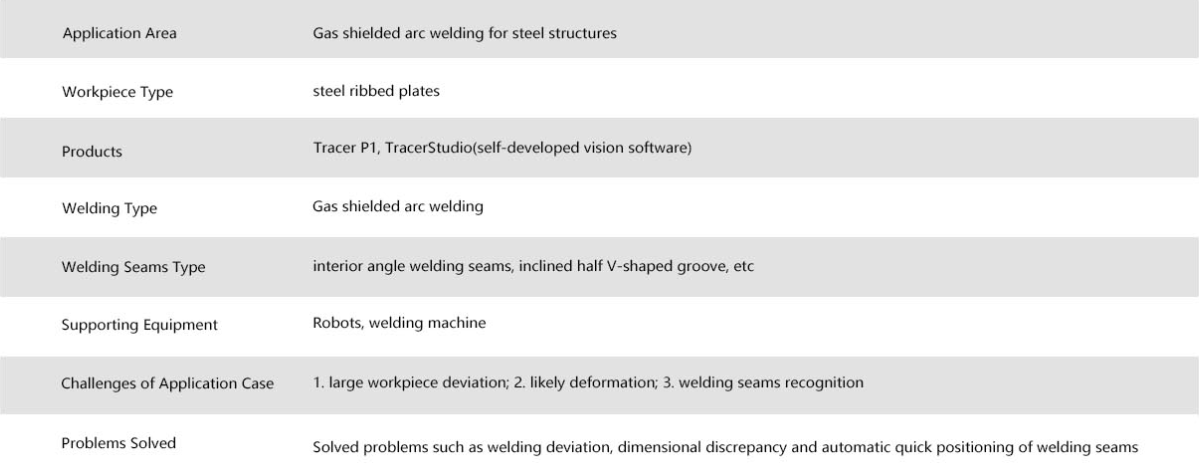

Faced with new challenges, the 3D vision automatic welding technology for steel bars from Revopoint 3D improves working efficiency and quality of steel welding massively. The technology adopts the 3D camera Tracer P1 to take high-precision photos along with TracerStudio software platform, which can analyze 3D point cloud data, identifying the location of the steel bar intersection, and providing parameters such as the location and type of the welding point to the robot by guiding the robot to complete the welding . Moreover, it only takes about 0.5 seconds to complete photos taking and analyzing. it can greatly improve work efficiency. The traditional 8-hour manual work cycle is replaced by non-stop welding for 24 hours a day, which can also reduce manual costs. In the meantime, the welding quality and consistency have been greatly improved due to precisely positioning and fine welding of the automatic welding technology for reinforcing steel bars.

Recommended Products and Services

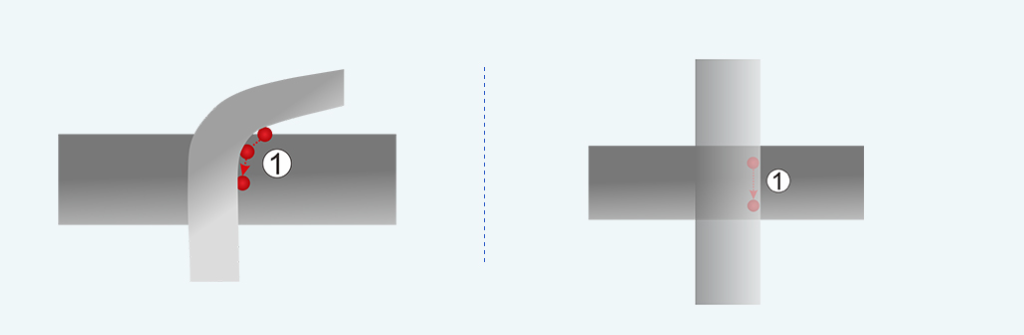

Solution Specifications

Applications

Being a wholly-owned subsidiary of China Railway Group, which is a large-scale construction enterprise managed by the state-owned Assets and Administration Commission of the State Council, also the leading enterprise in the domestic large-diameter shield, underwater shield tunnel and urban rail transit areas, the enterprise undertakes a lot of important infrastructure projects every year. It needs a steel segment to enhance the tunnel and subways for a longer lifespan and improved quality of infrastructure. In the past, a large number of workers weld steel segments manually, the production efficiency and quality are influenced heavily. However, Adopting the automatic welding technology for steel bars from Revopoint 3D , the problems of not being able to automate batch welding are solved due to different batches of workpiece and blanking errors , allow 95% of welding scenes to be unmanned .24-hour uninterrupted machine welding replaces the previous manual 8-hour welding, the human efficiency is improved by 300%. In the new generation of manufacturing era, the automatic welding solution for steel bars from Revopoint 3D is a key link to help companies realize automated productivity construction.

CHINA OFFICE

Office 902, 9/F, Tinno Building, Tongfa South Rd, Xili Street, Nanshan District, Shenzhen, 518000, P.R.China.

E-mail: cam.sales@revopoint3d.com

Skype: +86 18192151337

USA OFFICE

333 South Grand Avenue, Suite 403, Los Angeles, CA 90071